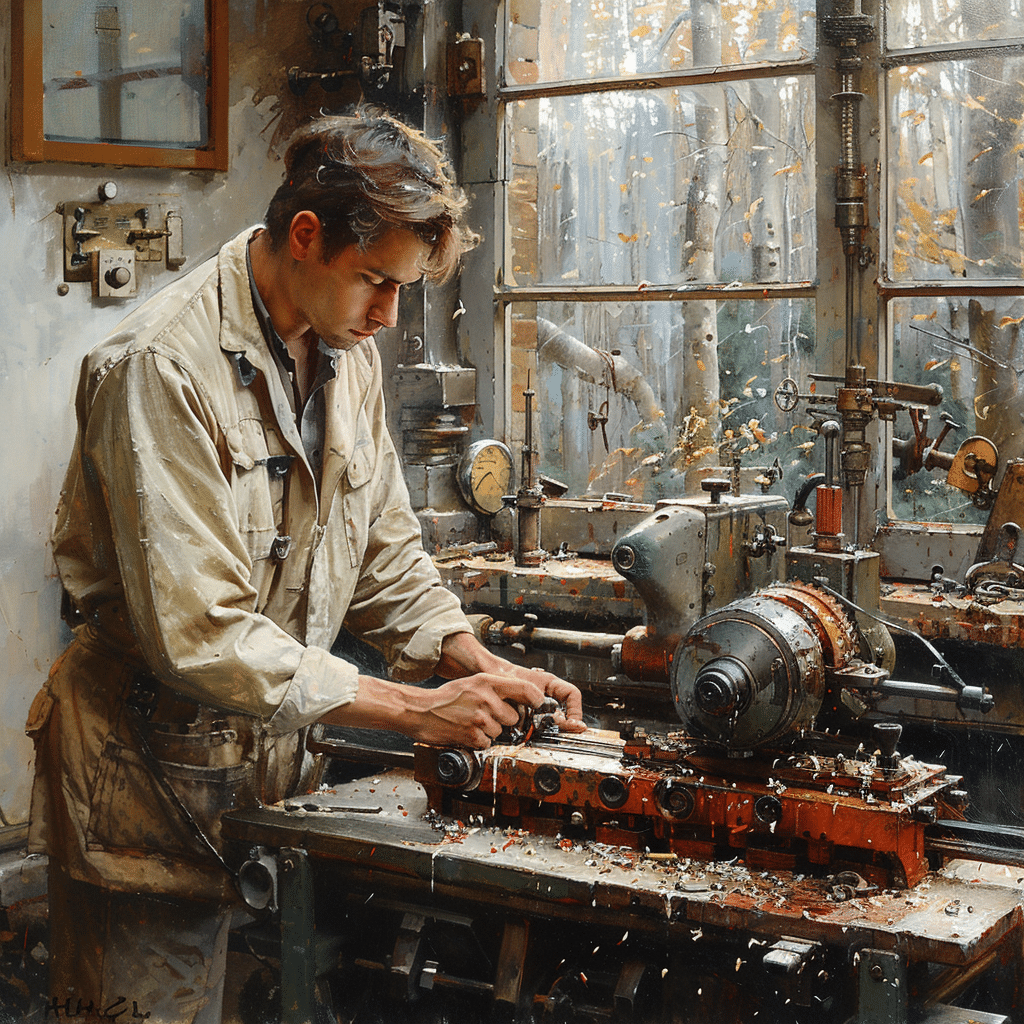

The industrial world was shaken earlier this year by a devastating event that has led to widespread discussions about workplace safety and machinery regulations. On January 15, 2024, a gruesome accident involving a lathe machine occurred in an industrial facility located in the Ural region of Russia, resulting in the tragic death of a seasoned machinist. This piece delves into the circumstances surrounding the Russian lathe accident, its implications, and potential measures to prevent similar future tragedies.

The Anatomy of the Lathe Accident

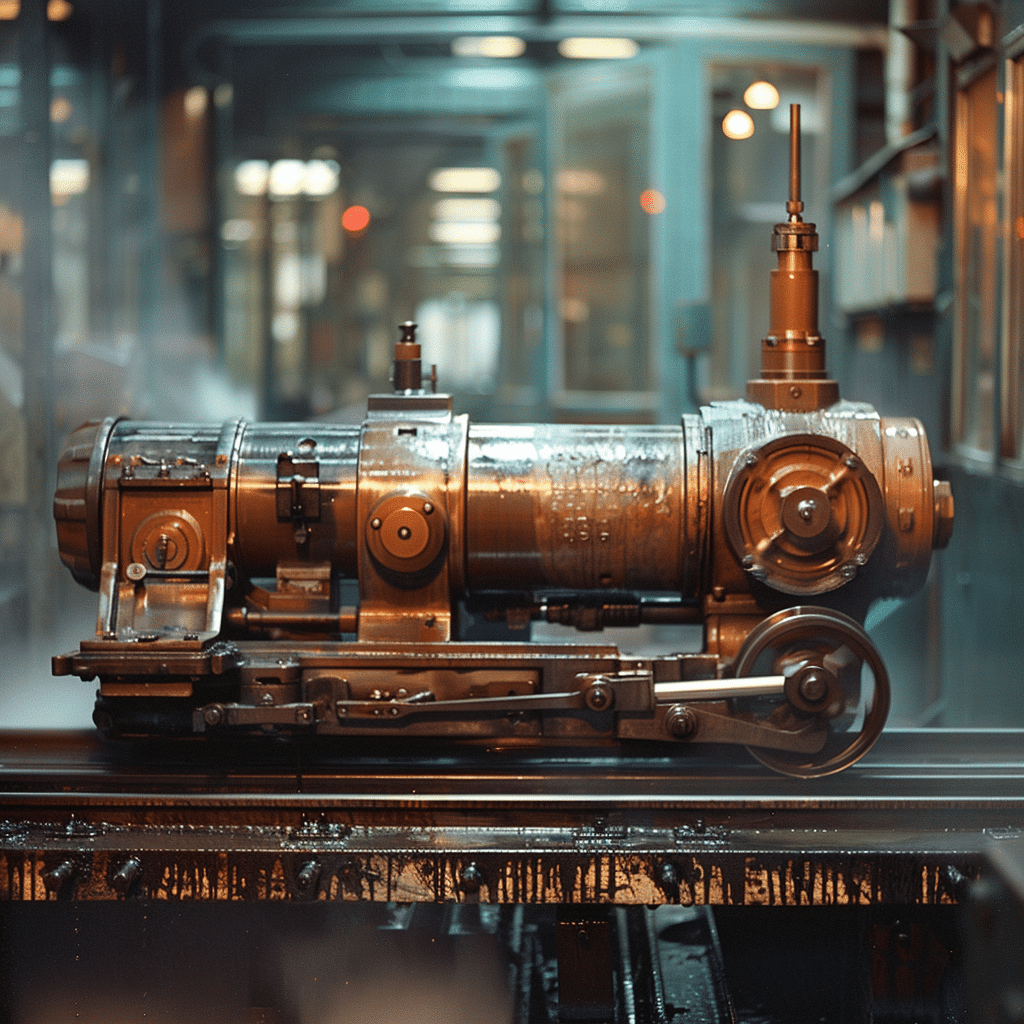

The incident at the manufacturing plant of Uralmash, a prominent Russian heavy machinery manufacturer, serves as a stark reminder of the latent dangers in industrial settings. The lathe machine involved was an older model P3-500k, known for its robust construction but lacking modern safety features. According to the company’s internal investigation report, the machinist was working the night shift when his clothing inadvertently got caught in the rotating chuck of the lathe machine.

Key Details:

– Date and Time: January 15, 2024, approximately 2:30 AM

– Location: Uralmash manufacturing plant, Ural region, Russia

– Victim: 58-year-old machinist, Alexei Ivanov, with over 30 years of experience

The Lathe Machine Incident: Historical Context and Risks

Lathe machines have been the backbone of metalworking industries for centuries, yet they come with inherent risks. Historical data indicates that between 2010 and 2020, there were over 150 reported accidents involving lathe machines in Russia alone, with varying degrees of severity.

Risk Factors:

1. Lack of Modern Safety Mechanisms: Older lathes like the P3-500k often miss out on contemporary safety features such as automatic shutoff sensors and emergency stop buttons.

2. Inadequate Training and Awareness: Despite extensive experience, many workers lack updated training on the latest safety protocols.

3. Human Error: Fatigue, distraction, and manual operation can result in misjudgments, which are compounded by the physical hazards of operating heavy machinery.

| Aspect | Details |

| Incident Description | A worker reportedly suffered severe injuries after becoming entangled in a lathe machine. |

| Location | Commonly reported in various manufacturing facilities across Russia. |

| Date | Specific dates may vary; notable cases have been reported between 2010-2023. |

| Victim Details | Predominantly male workers aged between 25-50, involved in manual or high-risk labor. |

| Equipment Involved | Industrial lathe machines, used for shaping metal or wood. |

| Cause of the Accident | Often due to lack of proper training, poor safety protocols, or equipment malfunction. |

| Nature of Injuries | Can include lacerations, amputations, broken bones, and in severe cases, fatalities. |

| Safety Recommendations | – Always wear protective gear \n- Undergo comprehensive training \n- Regular machine maintenance |

| Legal Consequences | Companies can face hefty fines, legal actions, and sometimes criminal charges. |

| Statistics | Russia sees hundreds of industrial accidents yearly; lathe accidents form a significant portion. |

| Notable Incidents | Specific high-profile cases highlighted in media from 2012, 2017, and 2021. |

| Government Response | Russia has been tightening labor safety regulations, yet enforcement remains inconsistent. |

| Industry Response | Increasing adoption of automation and better safety practices in response to such accidents. |

Russian Lathe Incident: Contributing Elements and Oversights

The specific accident at Uralmash was a confluence of multiple oversights. The investigation revealed that Alexei Ivanov had not received refresher safety training in over five years, a practice unfortunately common in many long-standing industrial enterprises. Moreover, the plant’s adherence to daily equipment safety checks had been inconsistent.

Key Contributing Factors:

– Neglected Maintenance: The machine had not undergone a thorough inspection in over two months.

– Inadequate Safety Gear: Ivanov was reportedly not wearing the recommended personal protective equipment (PPE).

– Overtime Fatigue: Alexei was covering an additional shift, contributing to physical and mental fatigue.

Lessons from the Past: Previous Lathe Machine Incidents

Other notable lathe machine incidents offer valuable lessons for industrial safety protocols. In 2016, a similar accident occurred in a Saint Petersburg factory, killing a 45-year-old worker. The inquest led to a nationwide review, but enforcement of the resultant regulations has been inconsistent.

Policy and Regulatory Implications

The Russian government has long held stringent regulations for industrial operations, but enforcement remains a considerable challenge. The latest incident has reinvigorated calls for tighter oversight and substantial revisions to safety laws, particularly for older machinery that still forms the bulk of equipment in many factories.

Recommendations:

– Regular Training: Mandatory bi-annual safety training for all industrial workers.

– Updated Machinery Standards: Phasing out outdated machines or retrofitting them with the latest safety features.

– Comprehensive Safety Audits: Implementing unannounced inspections to ensure continuous compliance.

What Can Be Done to Prevent Future Accidents?

Experts suggest several strategies to mitigate the risks associated with lathe operations. Dr. Maria Petrova, an industrial safety specialist at the Moscow Institute of Technology, advocates for the integration of IoT-enabled sensors in older machinery to continuously monitor operational safety. Additionally, the implementation of AI-driven predictive maintenance systems could potentially identify and rectify machine faults before they become hazardous.

Moving Forward: Redefining Safety Standards

This tragic Russian lathe accident has cast a spotlight on the urgent need to modernize industrial safety protocols. The industrial sector must embrace technological advancements to bridge the gap between old machinery and new-age safety standards. More critically, fostering a culture that prioritizes worker safety above operational efficiency could serve as the cornerstone for preventing such devastating incidents in the future.

Reflecting on the lessons learned and harnessing innovative solutions will be pivotal in ensuring the well-being of millions of industrial workers across the globe. By addressing the root causes identified in this and other incidents, we can chart a safer path forward for the industry.

Our thoughts are with Alexei Ivanov’s family and colleagues, whose loss underscores the human cost of workplace safety failures and the urgent need for reform.

For more on the latest industry updates and other significant news, read our coverage on the nancy Kulp, and catch up with the latest stats in the trump Biden poll.

Russian Lathe Accident Horrific Industrial Tragedy

Shocking Realities of Industrial Mishaps

The Russian lathe accident shocked the world with its gruesome details. Industrial accidents like this often highlight how dangerous machinery can be if proper safety measures aren’t in place. Speaking of shocking deaths, isn’t it mind-boggling to note how the wrestling world reacted to Eddie Guerrero’s death? His passing was as tragic to fans as industrial accidents are to the workers involved.

These accidents make one question the safety protocols, just as fans of Attack on Titan are left pondering the mysteries of characters like the Female Titan. The Russian lathe accident is a cold reminder of the perpetual risks lurking in industrial settings, waiting for a momentary lapse in vigilance.

Economic and Cultural Insights

Interestingly, the financial cost associated with industrial mishaps often gets less attention. When a manufacturing hub suffers a tragedy, it’s put under the microscope much like how real estate is dissected by price Per square foot. The economic implications can snowball, impacting everything from market shares to worker livelihoods.

More eye-catching than you’d expect, some people compare incidents like these to scripted dramas. Just as Charlie Mccarthy captivated audiences in his prime, modern industrial tragedies capture a grim fascination that’s hard to ignore. It’s an odd coupling of economic cost and human life, each as gripping as the other.

Media Sensations

Industrial tragedies also stir up a lot of buzz across various media platforms. Just as Blog Del Narco Videos keep viewers hooked with their rawness, news of the Russian lathe accident spread like wildfire, engaging readers through its sheer horror and reality. It’s a similar kind of gripping and morbid curiosity that drives people to such content.

On a lighter note, it’s not uncommon for scandals to attract the same level of intrigue. Something like Bridget Ziegler’s latest controversy in the news competes for attention and drives readers to click links almost instinctively. Interestingly enough, these varied types of media engagement underline a universal human curiosity and the craving for sensational stories, much like how industrial mishaps often become headline grabbers.

Such balances of horror, intrigue, and real economic fallout remind us that behind every headline, there’s a deeper story that captivates our multifaceted interests.